How is sound generated and transmitted in ducts? This question is studied in duct acoustics, a branch of acoustics. Why do we study duct acoustics? I hope that this post will complement my recent book Duct Acoustics for the answer.

According to the archeological findings, history of duct acoustics is as old human history. We may imagine it to have begun when a Stone Age human discovered that impressive sounds could be produced by buzzing into a hollowed-out animal horn, which is a non-uniform duct in technical terminology. This revolutionary discovery propagated over the planet, invoking the curiosity of our ancestors for the explanation of the phenomenon, and starting a never-ending period of research and development. Next breakthrough came when craftsmen had the idea of making prototypes of animal horns from the materials available in their times, such as wood, clay, ivory, or metal. This capability enabled them to test various duct shapes. They thus learned that impressive sounds could also be generated by blowing into manmade ducts not necessarily of the shape of an animal horn. Hence forerunners of the modern wind instruments were invented. Figure 1 shows the oldest surviving example. We see similar trumpets in varying lengths, sizes and shapes played in all continents in ceremonies and wars.

Beginning with Renaissance, trumpets began to be used for making music and hence evolved the modern trumpet, which is characterized by its bent tube and valve mechanism which the player uses to vary the tube length so that the chromatic scale is played evenly. In some Baroque trumpets, fingerholes are provided to get a similar effect; however, blowing into tubes with holes is generally considered to be the distinctive feature of wind instruments of the flute or clarinet type, the former having an as long history stream as the trumpet and was known in various forms and names in many ancient cultures. These instruments essentially consist of a straight tube which is usually slightly tapered with or without a cone and perforated along its length by several fingerholes. The flute player excites the resonances (notes) for a particular fingering by blowing directly, or through a slit in a mouthpiece, on to an edge of a hole on the tube axially or laterally. In the clarinet type instruments sound generation differs from the flute in that tube resonances are activated by vibrations of a reed mounted on the mouthpiece. In a pipe organ or bagpipe, the duct resonances are similarly excited, except that the wind is supplied from a pressurized air reservoir.

Although ‘blowing’ into ducts for exciting resonances has been a prominent human endeavor in all cultures since prehistoric times, the design of wind instruments has largely remained an art of craftsmen applying empirical skills built up over many generations. It was only by the end of 18th century that the wave equation for an inviscid quiescent medium was established and the resonance frequencies of hard-walled tubes with ideal end conditions could be predicted. This provided a reasonable understanding of sound production in wind instruments, although the issues concerning three-dimensional sound propagation and viscothermal effects were to be fully cleared a century later. These theoretical developments were consequential to the establishment of conservation laws of fluid dynamics, but interest in theoretical duct acoustics, the status of which by the end of 19th century is described in Theory of Sound by John William Strutt, 3rd Baron Rayleigh (1842-1919), was largely motivated by the tubes of wind instruments.

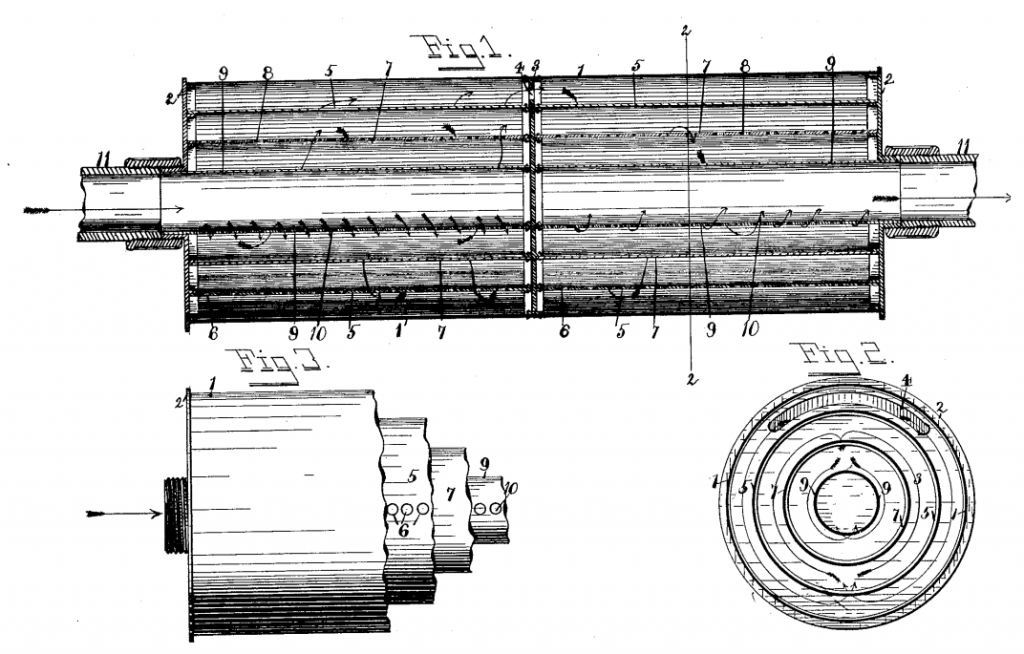

At around the same period of the history, the Industrial Revolution was taking place and positive displacement machines and turbomachines were being engineered and employed in industry in ever-increasing numbers. Thus, ‘blowing’ into ducts no longer was a human activity; fluid machines, such as piston engines, compressors, gas turbines and fans also excited duct resonances while discharging into an exhaust duct or admitting the working fluid from an intake duct, but the sound that is radiated from the open ends of the exhaust and intake ducts transpired to be a menace, not music, for the nearby people (and animals). This hazard was at first considered as an inevitable fact of technological development, but soon raised complaints. Thus, silencers were invented and fitted to exhaust and intake ducts. For example, Figure 2 shows the first patented silencer, which was used on motorcycle internal combustion engines. This muffler concept is still used today, usually with 2-duct units, in engines that can sustain relatively high exhaust back-pressures.

Till about the middle of 20th century, it was widely assumed that the silencers may be modeled in analogy with electrical filters. But the acoustic performance of so designed engine silencers was often inferior to predictions and, therefore, silencer design remained largely an empirical art involving many prototype tests.

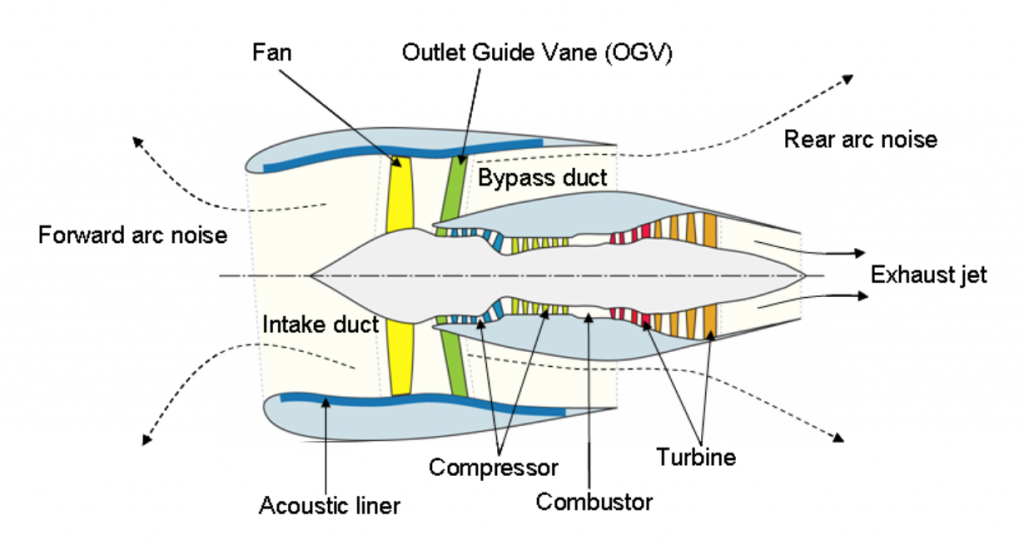

In the second half of the 20th century, there have been increasing concern on harmful effects of noise on human health and attempts on establishment of a legislative framework for the management of environmental noise. Legislation aimed, on the one hand, at the regulation of the noise at the source through establishment of permissible noise limits for automobiles, aircraft, railway, outdoor equipment, and recreational craft, and, on the other hand, at mitigating environmental noise at the point of the receiver. These measures on reduction of environmental noise have spurred, supported in the same era by the advent of digital computers and software which can simulate three-dimensional ducts and complex fluid flows, research in industry and academia on analytical, experimental, and computational duct acoustics. Today, silencing of reciprocating engines and turbomachinery ducting is practiced on a strong scientific footing. For example, in modern high bypass-ratio turbofan engines, a schematic of which is shown in Figure 3, the liners used in the walls of the inlet and bypass ducts can be designed so as the noise of the fan, which is dominant at both take-off and approach of aircraft powered by this type of engine, is attenuated in an optimal manner.

In this historical panorama, the objective of my book is to present a coherent narration of duct acoustics that will assist readers to acquire an improved understanding of the principles and the mathematical models that form the foundations of duct acoustics, and to develop analytical skills for acoustic modeling and analysis of ducts and duct systems. The scope of the treatise covers the acoustic aspects of the design of the intake and exhaust ductworks, mostly at subsonic low Mach numbers, of fluid machines of all types and sizes. The methods described in the book may also be used to model wind instruments. For example, an acoustic model of Tutankhamun’s trumpet would be a relatively simple exercise and can help to obtain an understanding of how it produces sound (see the caption of Figure 1). But space limitations prohibited inclusion of applications on design of wind instruments because the sounds of traditional instruments are judged by mental criteria that are built up from experience of playing music written for them over the centuries, rather than the richness of their sound quality, and, therefore, any useful treatment of the subject would require inputs from physiology, psychology, and musical arts.

So far, we considered manmade ducts, but intrinsic to human physiology are the mammal ducts of the circulatory system, vocal tract system and the ear canal, which also transmit acoustic wave motion. Mathematical modeling of these systems, which has received extensive attention in recent decades, is also within the capacity of the theories we describe but require additional inputs outside the present scope of the book. I hope that my book may serve as a background for readers interested in the design of wind instruments or the mathematical modeling of mammal duct systems, as well as in following the more advanced literature on duct acoustics.

Please note that I offer a complimentary copy of my educational software adem-edu when you get a hard-cover copy of Duct Acoustics (see my blog at https://ductacoustics.com).

Latest Comments

Have your say!